- Home Page

- Company Profile

-

Our Products

- Reverse Osmosis Plant

- Jar Washing and Filling Machines

- Mineral Water Plant

- Bottle Filling Machine

- Soda Soft Drink Plant

- Water Softening Plant

- Demineralization Plants

- EDI / Electrodeionization Process Plant

- Ultra Filtration System

- Pet Blow Moulding Machine

- BOPP Labelling Machine

- Bulk Shrink Machine

- Effluent Water Treatment Plant

- UV / Ultraviolet Disinfection System

- Swimming Pool Filtration Plant

- Pressure Booster System

- ISI/BIS Laboratory

- Sewage Treatment Plant

- Batch Coding Machine

- Glass Filling Machine

- Mixed Bed System

- Water Chiller

- Mixed Bed Deionizer

- Soda Filling Machine For Pet Bottle

- Mineral Water Filling Machines

- Bulk Shrink Wrapping Machine

- Swimming Pool Sand Filtration System

- UV Disinfection System

- More Info

- Contact Us

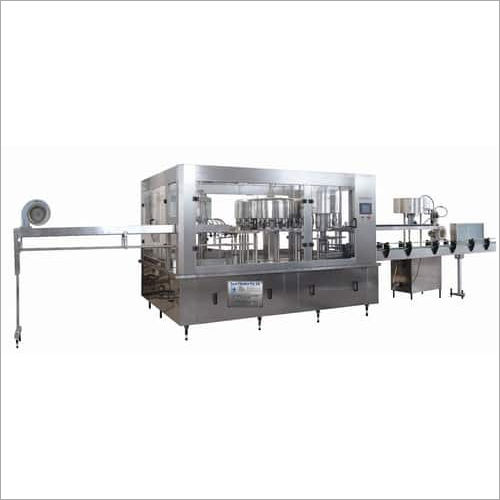

Semi Automatic Bottle Filling Machine

525000 INR/Unit

Product Details:

- Product Type FILLING CAP : 20 BPM

- Material RINSING CLONE MANUALLY

- Application Beverage, Food

- Computerized No

- Automatic Grade Semi-Automatic

- Control System Human Machine Interface

- Drive Type Electric

- Click to view more

X

Semi Automatic Bottle Filling Machine Price And Quantity

- 525000 INR/Unit

- 1 Unit

Semi Automatic Bottle Filling Machine Product Specifications

- Electric

- No

- 1 YEAR WARRANTY

- FILLING CAP : 20 BPM

- Beverage, Food

- Human Machine Interface

- 1200 BOTTLE PER HOUR Kg/day

- 800 Kilograms (kg)

- RINSING CLONE MANUALLY

- Silver

- Simple Control, High Performance, Low Noise, Lower Energy Consumption, ECO Friendly, High Efficiency, Stable Performance

- Semi-Automatic

Semi Automatic Bottle Filling Machine Trade Information

- 1 Unit Per Day

- 15 Days

- Yes

- Within a certain price range free samples are available

- All India

Product Description

Brief On Machine

The Premium Filling System consists of main structure, material transfer pump, product transmission belt with adjustable guide, material storage tank, Safety acrylic cover, pneumatic priming & stopping facility, filling pump, isolated transformer, electrical panel, motor, PLC & HMI,AC drive & storage tank. The special HIGH / LOW liquid level indication in the tank is an added advantage.

Salient Features of Premium Bottle Filling Machine

| The unit is made compact & versatile as per GMP norms | The structure is made of MS cladding with SS 304 |

| Rigid vibration free construction for trouble free performance | The contact parts such as filling nozzle, filling pump are made of SS 316 L |

| The Excel Filtration are used for the filling purpose | Easy to clean the base of the machine |

| The machine is supplied with easy to clean inbuilt storage tank | The storage tank is connected with the high capacity of material transfer pump |

| The storage tank is automatically controlled by the mean of float (Level) sensors | The process of priming, diving and blocking of the products done by pneumatic (air) operated cylinder |

| The Air pressure indicator attached with the machine to indicate the fault of low pressure of air supply | There is special feature called "PRIME" which is useful to suck the filling material from storage tank to nozzle end very quickly. More over this facility is useful to clean filling line (Silicon tubes) as well as filling pump |

| The machine has a facility of using "PRIME" function for all the pumps together or individual pumps also | Easy to operate PLC for any kind of filling volume adjustment |

| Each Filling head can be operated & monitored through PLC individually | Visible NRV glass is connected in the suction line |

| The each filling head can work independently | No change parts required for different size of products as well as different filling volume |

| There is a very less product change over time due to the very less usage of mechanical parts such as syringe set, mechanical seals, gear, chain, chain wheel etc | If there is no product during the filling process, the machine automatically stops and it gives the indication on HMI with inbuilt alarm system |

| To ensure the accurate filling process the level of filling material is required to be maintained. The machine takes care of the same with the help of PLC controlled ON / OFF material transfer pump (In between of middle level and high level) | Accordingly if the filling level goes down (Low level) then the machine will automatically stop and at the same time it will give the fault signal for Low level on HMI screen with inbuilt alarm system |

| Daily production ratio, production counter is given with the password protection | After the completion of the filling process, if the storage tank is required to be cleaned, there is no need to remove the storage tank. This cleaning process can be done very quickly with the help of inbuilt ball valve itself |

| Any kind of fault during the operation of the machine such as low pressure of air, low level of liquid, no product etc. can appear on the HMI with alarm facility, which can be easily attended to | PLC modes are user friendly and hence even less skilled operator can also handle the machine |

| The machine is supplied with isolated power supply to avoid adverse effect of electric supply | User friendly and less maintenance required owing to minimal usage of mechanical components |

| Most reliable and proven components such as Fests/SMC make pneumatic and electrical/electronic such as Bonfiglioli/Motovario make AC motor, Delta/Allen Bradley make Drives, PLC & HMI, Sensor LEUZE/BANNER/SUNX, MCB& relay "X" make | |

Technical Specification

| Model | HMPLPRERBF |

| Filling Range | Filling Range |

| Filling Volume | 10 ml Bottles |

| Filling Head | 4/ 6 / 8 / 10 / 12 Heads |

| Output Speed | 30 to 150 Bottles/Minute (depends upon viscosity of liquid & volume) |

| Working Height | 860 50 mm Adjustable |

| Power Consumption | 2.5 KVA |

| Power Supply | 3 Phase + Neutral + Earthling /415 V AC / 50Hz |

| Air Supply | 4 to 6 Kg/Cm |

| Net Weight | 500 Kg Approx. |

| Dimensions | 2100 mm (L)x 900mm (W)x 2000mm(H) Approx. |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese