- Home Page

- Company Profile

-

Our Products

- Reverse Osmosis Plant

- Jar Washing and Filling Machines

- Mineral Water Plant

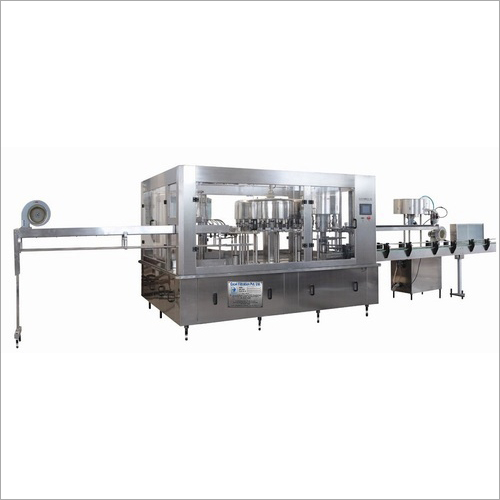

- Bottle Filling Machine

- Soda Soft Drink Plant

- Water Softening Plant

- Demineralization Plants

- EDI / Electrodeionization Process Plant

- Ultra Filtration System

- Pet Blow Moulding Machine

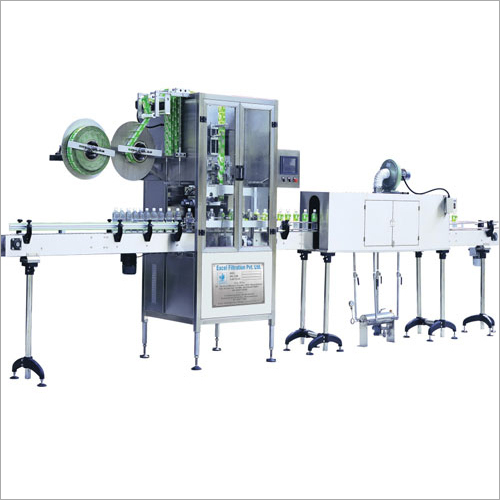

- BOPP Labelling Machine

- Bulk Shrink Machine

- Effluent Water Treatment Plant

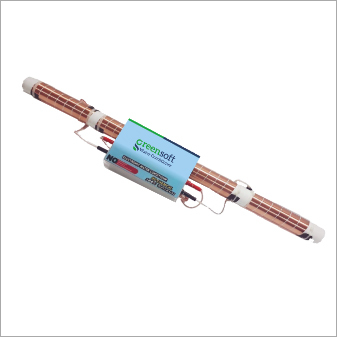

- UV / Ultraviolet Disinfection System

- Swimming Pool Filtration Plant

- Pressure Booster System

- ISI/BIS Laboratory

- Sewage Treatment Plant

- Batch Coding Machine

- Glass Filling Machine

- Mixed Bed System

- Water Chiller

- Mixed Bed Deionizer

- Soda Filling Machine For Pet Bottle

- Mineral Water Filling Machines

- Bulk Shrink Wrapping Machine

- Swimming Pool Sand Filtration System

- UV Disinfection System

- More Info

- Contact Us

Showroom

Our RO Plant or Reverse Osmosis Plant is an assembling plant where the procedure of switch osmosis happens. A normal current turn around osmosis plant needs six kilowatt-hours of power to desalinate one cubic meter of water.

Jar Washing and Filling Machines are widely used in various industries for filling as well as washing jars of different sizes, shapes and designs. These are highly reliable, easy to use, corrosion resistant and durable. Accessible in different features and designs.

Our Mineral Water Plant and Water Packaging Plants are a total framework in itself and are prepared for quick use. Our filtered water venture plan of action deals with the standards of advanced execution. The hardware and in addition the funneling and valves are altogether produced using S.S. - 316 guaranteeing their ideal execution.

Offered range of Bottle Filling Machine is provided in various nozzle number and filling capacity based options. This low noise machine is preferred for its low water wastage rate, low operating cost and high output level. This automatic machine ensures about its error free operation.

This Soda Soft Drink Plant is accessed in automatic operating mode. It uses gas based liquid as its filling material. Made of 316 or 304 grade stainless steel, this machine can be obtained in different working capacity options. Application of clip bottleneck technique, utilization of food grade steel made contact parts and high speed operation are its key factors.

Water Softening Plants are genuinely simple to work and keep up. Every one of that should be done after establishment is to intermittently include sodium chloride and the water conditioner wraps up. Sodium salts are not hard scales framing so water sans the calcium as well as magnesium salts is called delicate water.

Demineralization Plant is much of the time utilized where stringent prerequisites for low substance of salt and silica apply. Counter currently recovered, in this way streamlining the use of the recovery chemicals. Self-cleaning, consequently guaranteeing a consistent, low weight misfortune.

Reverse osmosis technology based EDI / Electrodeionization Process Plant is used for producing industrial grade process water and boiler water. It uses water obtained from sea, river and underground for its operation. Made of 304 grade stainless steel, this plant is equipped with spacious deionization chamber.

Provided Ultra Filtration System can be utilized for the expulsion of particulates and macromolecules from crude water to create consumable water. It has been utilized to either supplant existing optional and tertiary filtration frameworks utilized in water treatment plants or as independent frameworks in disengaged locales with developing populaces.

PLC controlled Pet Blow Moulding Machine is used for fast production of hollow plastic containers and bottles. This low cost equipment is reckoned for its hygienic operating environment, simple installation process and advanced security functions. Low cost operation and trouble free maintenance are its main attributes.

BOPP Labeling Machine is used for effective application of label on bottles and containers. This high performance machine is equipped with advanced conveyor system, electronic testing eye and photoelectric tracing components. Error detection arrangement of this machine ensures about its utmost precision level.

In every Bulk Shrink Machine, the items are wrapped utilizing a plastic therapist wrap film, which, when warmed, psychologists and takes the state of the item to protect it from dampness, harm and earth while being delivered.

Effluent Water Treatment Plant is used for disposal of industrial waste water by filtering it through multi stage water treatment procedure. This plant is instrumental in effective removal of high ph content, COD, BOD, color and various other contaminants present in waste water.

The UV or Ultraviolet Disinfection System is intended to guarantee that all microorganisms get adequate introduction to the UV light (dose).Based on the pressure driven properties of water; the reactor should be advanced to control the stream in a way in order to expand living arrangement time and lift turbulence.

Electricity driven Pressure Booster System is widely used to improve water pressure of irrigation system, motor driven booster pump and water supplying system. It consists of pump controller for maintaining precision of its operation. Assembled valve and pipe structure of this system guarantee about its reliable functioning.

Sewage Treatment Plant is used for effective removal of ammonia, COD and BOD present in sewage water. Known for its automatic functioning, this plant is widely used in residential areas, Emission rate of this plant conforms to industry specified standards.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free